- The basic machine, 1 lanes can produce up to 30 K cups per min.

- Pneumatic system driven carrier plates, very easy to maintain and clean.

- Handle different capsule styles with easy size changeover.

- Small footprint layout, easy to use and maintain.

Brief Introduce:

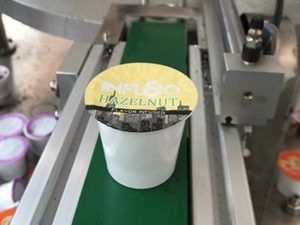

K cups are the best seller of single serve coffee in the North American market. We have helped many small and startup companies to produce their own brands K cups to the market.

The AFPAK AF-HK1 K cup filling sealing machine is a fully automatic machine and very popular because it’s small size and easy to use.

We have built this machine to produce K cups, K shots, and similar cups.

This is a customize-built machine, you can use your own designed capsules in this machine.

It is suitable for packaging a wide range of liquid, paste, granulated and powdered products, you can use this machine to fill dairy products, soluble powders, coffee, salads, dressings, desserts, dry soups, frozen dished, cosmetics, and so on.

Thanks to the exceptional designs in mechanical and program, this machine guarantees the most reliable production performance.