What is a pouch packaging machine?

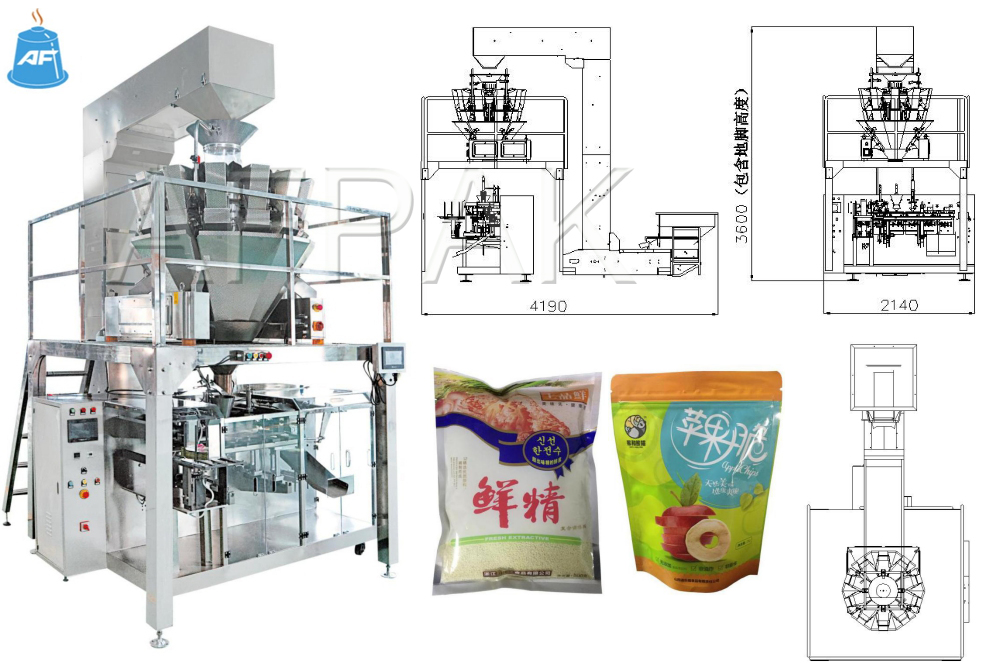

The pouch packaging machine is usually composed of two parts: a bag feeding machine and a weighing machine. The weighing machine can weigh-type or a screw-type, pack particles, powders, and liquid materials. The pouch packaging machine can replace manual packaging and realize packaging automation for large enterprises and small and medium-sized enterprises. The operator only needs to put the finished pouch in the bag, taking part in the equipment. The pouch packaging machine equipment will automatically grab the bag, print the date, open the bag, and give the measuring device to measure blank, seal, and output. Its characteristic is that the manipulator replaces manual bagging, which can effectively reduce the bacterial contamination in the packaging process, and at the same time, improve the level of automation. It is suitable for small-size and large-volume automatic packaging of food, condiments, and other products. Customers can also add detailed functions such as door opening emergency stop, automatic card insertion, and abnormal discharge according to product packaging requirements. The pouch packaging machine’s working process does not require manual operations, improving production efficiency for enterprises, saving labor costs and management costs, and greatly reducing enterprise costs.

Application of pouch packaging machine

# Food and beverage industry

Ice cream, fudge, yogurt, syrup, honey, alcohol, vinegar, oil, mayonnaise, jam, ketchup, salt, coffee powder packaging, milk powder packaging, spice powder, etc.

# chemical industry

Fertilizer powder, detergent powder, other powdered chemicals, paints, printing inks, coatings, construction sealants, adhesives, anti-rust treatment, cutting fluids, thread locks, mold release agents, isopropanol, acetone, methanol, dilution Agents, bleaching agents, detergents, deodorants, disinfectants, degreasing agents, etc.

# Medical and pharmaceutical industry

Granules, vitamins, minerals, cough syrup, cold and flu medicine, paracetamol suspension, sports nutrition, anesthetics, solvents, eczema ointment, acne treatment, lotion, sunscreen, skin care products, foot care products, ear drops, Reagents, eye drops, lubricants, etc.

# Cosmetics industry

Foundation, makeup remover, cream, nail polish, nail polish remover, lotion, mask, hair removal wax, hair dye, hair wax, hair spray, shampoo, conditioner, liquid soap, shower gel, deodorant, toothpaste, perfume, Body spray, massage oil, etc.

# Automotive industry

Automotive lubricants, screen cleaners, degreasers, shampoos, polishes, air fresheners, leather care, paints, wax oils, chain lubricants, sunshade cleaners, cleaners, puncture repair products, hydraulic oils, paints , Varnish, antifouling liquid, etc.

# Household goods industry

Fabric softener, disinfectant, bleach, window cleaner, toilet cleaner, floor cleaner, paint, white oil, brush cleaner, paint remover, adhesive, fertilizer, insecticide, herbicide, weeding Agents, fragrances, dispersants, air fresheners, deodorants, leather cleaners, leather dyes, fabric protectors, shoe polishes, shoe cleaners, etc.

How does a pouch packaging machine work?

The pouch packaging machine comprises bag sealing rotation system software and vacuum pump sealing rotation system software. The vacuum pump vessel system software is a constant frequency away from rotating fitness exercises. Manual visualization is beneficial; time-saving and labor-saving for bag replacement; automatic and unmanned metrological verification and packaging after entering the daily task proposal; monitoring systems for machinery and equipment that do not meet the packaging standards without feeding or sealing; The bag packaging machine immediately heats the sealing application to make the packaging flat and durable. The rotary automatic pouch packaging machine grabs the pre-made bags at a speed of 200 packs per minute, fills and seals the products. This process involves moving the bag in an intermittent rotating manner to different “stations” placed in a circular layout. Each station performs various packaging tasks.

1. On the bag

We put the finished packaging bags on the bagging part of the pouch packaging machine and then suck the bags through the vacuum suction cups and convey them to the bag clamping station one by one to realize the bag conveying work. This is also the first station.

2. Clip the bag

When the proximity sensor detects the bag, the pouch packaging machine arm picks up the bag and then transfers it to a set of holders. When the bag moves around the rotating unit to different “stations,” these bag holders will clamp the bag. Live in the bag. These bag holders can continuously support up to 10 kg of weight on the best bag filling and bag feeding machine models.

3. Optional printing date

If you need to print the date, place the pouch packaging machine on this station. The bagging and sealing machine can use a thermal printer and inkjet printer at the same time. The printer can place the required date/batch code on the packaging bag. The embossing option puts the raised date/batch code in the bag seal.

4. Zipper or open bag detection

If the bag has a zipper opening and closing, the vacuum suction cup will open the lower part of the preformed bag. And the opening claw will grab the top side of the pack. The opening jaws are separated outward to open the top of the bag, and a blower inflates the prefabricated bag. If the bag does not have a zipper, the vacuum pad will still open the bag’s bottom but will only engage the blower.

There are two sensors at the bottom of the bag to detect the presence of the pack. If the bag is not caught, the filling and sealing station will not engage. If there is a bag, but it is not placed correctly, the bag will not be filled and sealed but will remain on the next cycle’s rotating device.

5. Bagged

The product is usually dropped from the bag funnel to the bag via a multi-head weigher. For powder products, use auger filler. The product is pumped into the bag through a liquid filler with a nozzle for liquid bag filling machines. The pouch packaging machine is responsible for the correct measurement and release of the discrete amount of product to be dripped into each prefabricated bag.

Options for other devices include:

Flushing gas: This modified atmosphere packaging (MAP) process uses explosive gas (usually nitrogen) to replace the bag’s oxygen. This is done immediately before filling the pack with the product to ensure maximum displacement.

Dust collection: For dusty or messy products, place a dustcover above the gas station to collect particulate matter in the air.

6. Sealing of the bag or other options

Sometimes, loose contents need to settle to the bottom of the bag before sealing. This station can achieve the purpose by gently shaking the prefabricated bag.

Other options for this station include:

Second liquid seal: For the liquid/water bag filling machine configuration, this workstation can be used for the second liquid seal to ensure maximum seal integrity.

Second station: For products that contain both solid and liquid ingredients, a second filling station can be added here.

Loading shelf: For heavier fillings, a shelf can be added after filling to bear the load of extra weight and reduce the pressure on the clamping arm.

7. Bag sealing and deflation

Before sealing, the pouch packaging machine squeezes the remaining air out of the bag through two venting parts. The heat seal is closed on the upper part of the bag. The prefabricated bag’s sealing layers are bonded together to form a tight seam by heating and pressing.

8. Cooling and discharge

The cooling rod of the pouch packaging machine passes over the seal to strengthen and flatten it. The finished bag is then unloaded into a container or conveyor. and it can be transported to offline equipment, such as automatic check weigher, X-ray machine, box packaging, or carton packaging equipment.

The above eight steps are the working process of the pouch packaging machine. The eight-station is the most common and common pouch packaging machine in the market. Customers can increase or decrease according to their needs.

What are the advantages of the pouch packaging machine?

- The pouch packaging machine is easy to operate. It adopts PLC control, and is equipped with a touch screen man-machine interface control system, which is easy to operate

- Frequency conversion speed regulation, the pouch packaging machine uses a frequency conversion speed regulation device, and the speed can be adjusted at will within the specified range.

- The pouch packaging machine has an automatic detection function. If the bag is not opened or the load is incomplete, there is no feeding or heat sealing. The bag can be reused without wasting materials and saving production costs for users.

- The pouch packaging machine has a safety device. When the working air pressure is abnormal, or the heating tube fails, it will alarm.

- The pouch packaging machine adopts the horizontal bag feeding method. The bag storage device can store more packaging bags. The quality of the bag is lower, and the bag splitting and bag loading rate are high.

- a motor controls the bag width adjustment of the pouch packaging machine. Press the control button to adjust the width of each group of machines. At the same time, which is convenient to operate and save time.

- The pouch packaging machine part adopts imported engineering plastic bearings, no need to refuel, reducing the pollution of materials;

- The pouch packaging machine uses an oil-free vacuum pump to avoid pollution of the production environment.

- The zipper bag opening mechanism is specially designed for the characteristics of the zipper bag opening to avoid deformation or damage to the bag opening

- The loss of packaging materials is low. The pouch packaging machine uses prefabricated packaging bags. The packaging bags have perfect patterns and good sealing quality, which improves the product quality.

- Comply with the hygiene standards of the food processing industry. The parts and components of the pouch packaging machine that come into contact with the material or the packaging bag are made of stainless steel or other materials that meet the food hygiene requirements to ensure the food’s hygiene and safety.

- The pouch packaging machine has a wide range of packaging. It can be suitable for packaging liquids, sauces, granules, powders, irregular blocks, and other materials by choosing different meters.

- The packaging bag of the pouch packaging machine has a wide range of applications. It can be applied to prefabricated bags and paper bags made of multi-layer composite film, silica, aluminum foil, single-layer PE, PP, and other materials.

conclusion

It is recommended that when choosing a pouch packaging machine, choose a reliable manufacturer to ensure the after-sales service of the bag packaging machine. During the use of the equipment, customers need to consider the failure of the pouch packaging machine during use. Semi-automatic models are relatively easy to handle, and some large-scale fully automatic models involve more technical points. If the equipment fails and cannot be repaired in time, it will be a production loss for your company. Therefore, while choosing the equipment, you need to find more powerful manufacturers for comparison and then choose the most suitable manufacturer for cooperation.